GLS TANKS - EVERYDAY STEELS

At Everyday Steel ™ we pride our experience team,best technical solution continue innovation and best services in the world. With 7+ years of experience in manufacturing, erection facility we have started and committed to create innovative Ideas for Storage Tanks and Storage Silos through constant research and development. We are pledged to deliver the best quality and innovative technologies to our clients, keeping up with the ever-changing requirements of the industry. Our company/team has earned an expertise in fabricating and engineering steel structures in multiple dimensions. We provide design & manufacturing engineering support, outstanding customer service, consistent product quality, and on-time delivery of our products. The combination of our Zincalume technology and our experienced engineering staff allows us to Serve our clients best.

Our Capabilities & Investigations

- Our Manufacturing unit is Set up to 1000 sq mt in Greater Noida.

- All our products are ISO certified and also certified by chartered structural engineers for longevity and durability.

- Our capabilities to make cylindrical tanks from 10 Cubic meters to 6,000 cubic meters and Grain silos from 50MT to 12,500MT in volume.

- Everyday Steel Team has wide experience of handling turnkey projects in India and export markets in Nigeria, Chad, Zambia, Egypt, Sudan, Dubai, Thailand, Philippines, Nepal and many more.

- Everyday Steel Steels uses the best of all the world with the technology from USA, Raw material from Australia and manufacturing in India. This gives us the advantage of offering most advanced state of the art product with most competitive pricing.

Everyday steel's Technology & Durability

Everyday Steel ™ in a strong corrugated profile and are stiffened with unique ‘W’ stiffeners with much higher strength and reliability than normal one. Our unique profiled technology of uniform pitch and depth makes it a premium one as it acts as a structural reinforcement and shock absorbed for earth movement or soil subsidence.

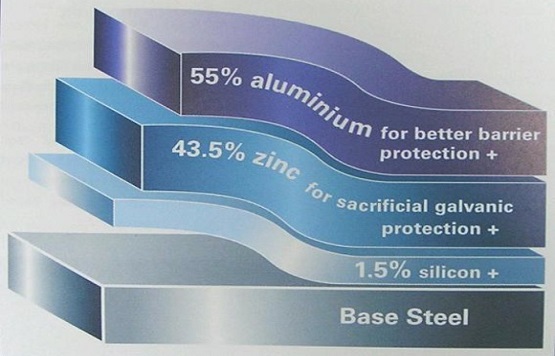

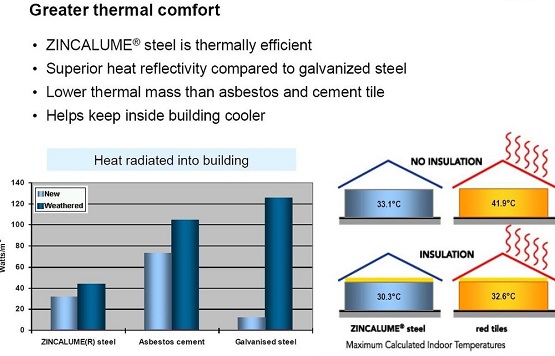

Zincalume steel was first released by Blue Scope steel in 1976 and very quickly replaced Galvanized steel in the construction market largely due to Zincalume superior corrosion resistance and long life; Zincalume has 4 times the life of Galvanized steel;The composition in which the steel sheets are dipped is made up of 55% aluminum, 43.5% zinc and 1.5% silicon. This coating is done at a temperature of 600C and combines superior corrosion resistance of aluminum with the cut edge protection of zinc. Material used in tanks & silos are ZINCALUME® Steel manufactured by Tata Blue scope; an equal joint venture between Tata Steels Ltd. and Blue scope Steels of Australia.Our ZINCALUME® steel has both the galvanic/sacrificial protection and barrier protection which makes it the most preferred option for roofing and walling applications around the world.

ZINCALUME® Steel has an alloy coating weight of 55% Aluminum (80% by Volume), 43.5% Zinc & 1.5% Silicon with 150gram/m2 coating weight is distributed equally on both sides of the coated strip. These sheets worldwide have set the standard for corrosion resistance and long life and are manufactured as per Australian Standard AS 1397:2002, American Standard ASTM A792M and Indian Standards IS 15961:2012 & ISO 9364. We provide ZINCALUME® steel which is extensively tested in laboratory and in actual conditions, to evaluate its corrosion resistance performance in different environments. It is particularly preferred for the tropical climates and marine environments.

Glass-Fused-to-Steel / Glass-Lined-Steel

Glass-Fused-to-Steel (GFS), also known as Glass-Lined-Steel (GLS), is the ultimate tank and silo solution utilizing a proven product with significant benefits to customers, consultants, and contractors over other types of tank construction. GFS is two material (Molten glass reacts with the steel plate surface) are fused together to form an inert and inorganic bond, which combines the strength and flexibility of steel and outstanding corrosion resistance of glass, so Glass-Fused-to-Steel tanks can provide many advantages over standard epoxy or welded painted storage tanks. GFS tanks has flexibility to remodel, extension, dismantle and relocation.

Applicable / implementable area for GFS/GLS Tanks

Glass-Fused-to-Steel (GFS), is widely used for the storage of Vegetable Oils or Dry Bulk Solids. These tanks are mostly designed to store in various areas of municipal corporation in the use of Sludge Storage, Sludge treatment and Mesolithic Digester. GFS/GLS tanks is applicable to store Drinking water,Thermophylic Digester, High Temperature Applications and Aggressive / Chemical Industrial Effluent

Benefit & Features Characteristics of GFS/GLS Tanks

- Safe and secure storage with low operational and maintenance costs.

- Easy and Rapid installation of GFS/GLS Tanks.

- Ease of transport to site.

- Tanks can be extended, dismantled and re-sited giving long term asset value.

- Long life and Most cost effective storage solution to meet customers needs.

Reference by ;- https://www.everydaysteels.com/

No comments:

Post a Comment